Ryman Healthcare Riccarton

Mass Timber Apartment Building in an Aged Care Development

In this project, the engineer was able to reduce seismic load and decrease the period by using Tectonus DFFJ dampers on mass timber shear walls in a multi-unit apartment building in Christchurch.

Ryman Healthcare, Riccarton Park

Ryman Healthcare is NZ’s largest retirement village operator, providing a home to 13,000 people.

Ryman Riccarton Park is their latest development right next to the eponymous racecourse in Christchurch. The development consists of townhouses, apartments, serviced apartments, dementia, hospital care and rest home facilities, with a range of village amenities.

Structure Design and Tectonus developed a solution for the apartment buildings which are to be multi-unit residential buildings constructed completely from mass timber.

A commitment to sustainable and resilient design

Ryman chose to make two big commitments in design and build of the main apartment buildings: 1) a commitment to low carbon, and 2) a commitment to high seismic resilience.

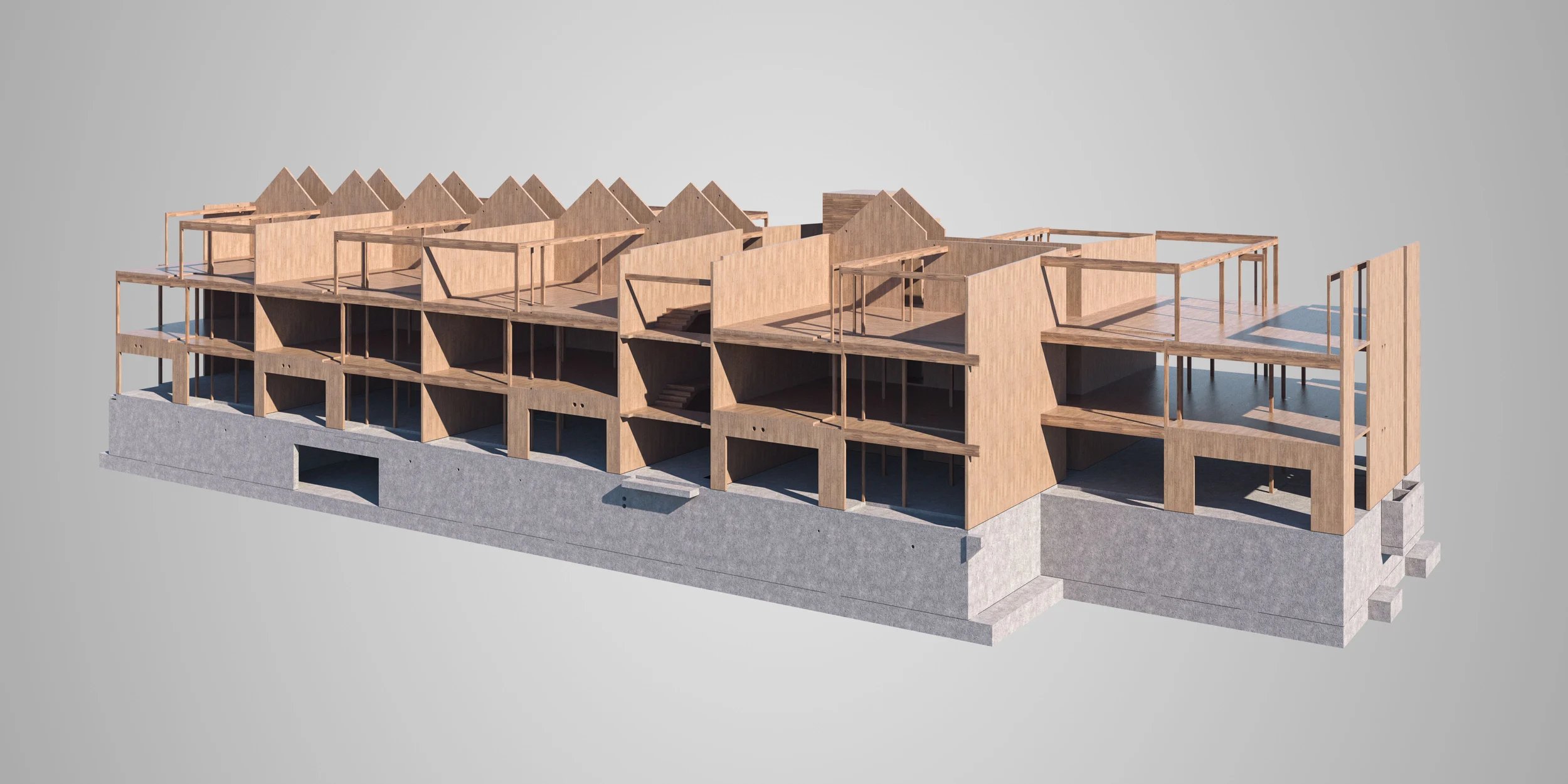

The three 3-storey multi-unit residential buildings are to be constructed from mass timber. Whereas many mass timber buildings in high seismic areas are built with steel or concrete lateral systems, Ryman’s vision was to go 100% timber and utilize a ‘panelised’ construction approach. This introduced the need for an innovative structural design for which they turned to structural engineers Micthell Vranjes and NZ mass timber experts Structure Design.

Second, Ryman is committed to high seismic resilience. Being in Christchurch where the 2010/2011 Earthquakes live on in peoples’ memories, and being home to hundreds of senior citizens, they insisted that the buildings be of a low-damage design. The building should cope comfortably with a smaller ‘SLS’ event, and residents should be able to return almost immediately following a larger design-level earthquake.

The commitment to high seismic resilience is not new – Ryman’s Petone village features NZ’s first base-isolated apartment building which demonstrated its performance in an earthquake in 2016.

Seismic Design Challenge

Building with mass timber is still relatively new and building with mass timber in high seismic regions, like Christchurch, has unique challenges particularly when both the floors and structure are to be constructed using mass timber.

The design concept was for a ‘balloon-type’ structure with shearwalls extending from ground to roof-level. The number of shearwalls was determined by the number of inter-party walls needed between each unit. In total, the building would have 20 shear walls making the building quite stiff.

Dealing with the seismic loads became a challenge for the engineers with what started out as a conventional design using conventional hold-downs with normal timber fasteners. In addition, the period was such that the building could experience significant accelerations which could expose the occupants and their belongings to high G forces in a seismic event.

This is what led Structure Design to talk to Tectonus. Adding damping devices as hold downs on the shear walls could reduce the loads and decrease the period.

Design solution

Structure Design engaged the Tectonus engineering team to work on the design which went through several iterations to get to the best result within the constraints of the project.

Eventually, two Tectonus Damage-Free Friction Joints (DFFJs) with either 65 kN or 85 kN capacity were installed on each shear wall. DFFJ is a friction joint that provides repeatable fully elasto-plastic performance without stiffness degradation.

Building deadweight would allow the building to recentre. Forces would be concentrated in the devices rather than the timber. In the event of an earthquake, this would allow the residents to stay in their homes whilst any repairs are undertaken.

Knife plate connections with dowels were specified to connect the top of the devices to the CLT panels. The bottom of the devices will be anchored to the foundation using a steel bracket. Spherical bearings were specified at the bottom of the devices to ensure displacement compatibility for in- and out-of-plane deformation of CLT walls.

Results

Analysis showed the system could achieve a global ductility of around 3.0. This relatively high ductility value for a mass timber system combined with low over-strength factor of the devices made the design economical compared to a conventional design.

Furthermore, this significantly reduced the number of fasteners used throughout the building. Fasteners are normally one of the expensive components of mass timber systems, so a reduction in the number of fasteners can achieve significant cost savings.

The devices are designed to be able to take 2.5 times the design displacement to ensure the structure is protected for large rare events that are stronger than design-level earthquakes.